You Are Here:Home > Information dynamic

> Industry Trends

News Navigation

Why is it said that formaldehyde free ENF grade environmentally friendly particleboard has low forma

source:www.xindongfang.net.cn Time:2025-05-12

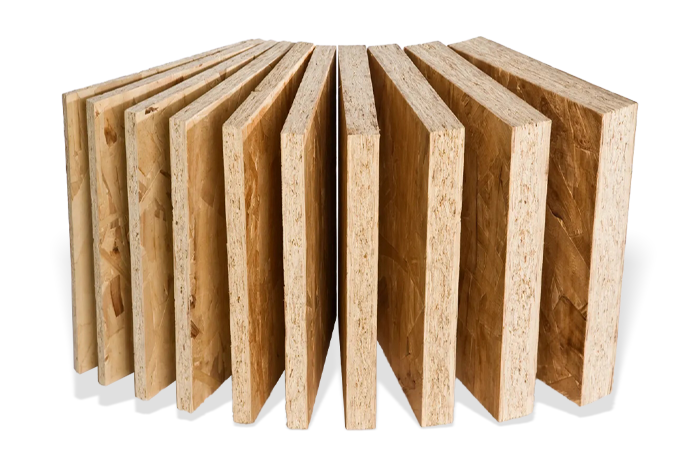

The low formaldehyde emission of ENF grade environmentally friendly particleboard is mainly due to a series of effective measures taken in raw material selection, production process, and quality testing, as follows:

1. Excellent raw materials

Wood raw materials themselves have low formaldehyde content: Non formaldehyde ENF grade environmentally friendly particleboard usually uses high-quality wood as raw materials, such as pine, poplar, etc. These woods have a relatively low amount of formaldehyde during their growth process, which reduces the initial formaldehyde content of the board from the source.

Using formaldehyde free or low formaldehyde adhesives: The urea formaldehyde resin adhesive used in traditional particleboard is one of the main sources of formaldehyde. The formaldehyde free ENF grade environmentally friendly particleboard adopts new formaldehyde free adhesives, such as MDI adhesive (isocyanate adhesive) or other biological adhesives. These adhesives do not release formaldehyde during production and use, fundamentally eliminating formaldehyde pollution caused by adhesives.

2. Good production process

Optimization of hot pressing process: During the hot pressing process, by correctly controlling parameters such as temperature, pressure, and time, the adhesive inside the board is fully cured, while avoiding the occurrence of formaldehyde caused by adhesive decomposition due to overheating or uneven pressure. The optimized hot pressing process can also make the board structure denser, reduce internal pores, and thus lower the release channels of formaldehyde.

Proper drying treatment: Drying wood raw materials is an important step in the production of particleboard. During the drying process of formaldehyde free ENF grade environmentally friendly particleboard, excellent drying equipment and processes are used to control the moisture content of the wood within a suitable range (generally 8% -12%). Appropriate moisture content not only helps improve the physical properties of the board, but also reduces the increase in formaldehyde emissions caused by excessive or insufficient moisture.

Surface treatment technology: Some formaldehyde free ENF grade environmentally friendly particleboard will use special surface treatment techniques, such as edge sealing treatment, veneer treatment, etc. Excellent edge sealing materials and techniques can seal the edges of the board, preventing the release of formaldehyde from the inside. Veneer treatment can form a protective film on the surface of the board, reducing the volatilization of formaldehyde from the board surface.

3. Strict quality inspection

Internal inspection of enterprises: Enterprises producing formaldehyde free ENF grade environmentally friendly particleboard usually establish a strict internal quality inspection system and conduct formaldehyde emission testing on each batch of boards. Enterprises will be equipped with excellent testing equipment and professional testing personnel to test the boards according to standards or stricter enterprise standards. Only products that pass the testing can enter the market.

Third party testing and certification: In addition to internal testing within the enterprise, formaldehyde free ENF grade environmentally friendly particleboard also needs to be tested and certified by third-party authoritative organizations, such as relevant quality inspection departments or professional certification agencies. These institutions will test the boards according to strict standards and procedures to ensure that they meet the formaldehyde emission requirements of ENF level, and issue corresponding certification certificates. This third-party testing and certification has high authority and credibility, and can provide consumers with reliable quality assurance.

1. Excellent raw materials

Wood raw materials themselves have low formaldehyde content: Non formaldehyde ENF grade environmentally friendly particleboard usually uses high-quality wood as raw materials, such as pine, poplar, etc. These woods have a relatively low amount of formaldehyde during their growth process, which reduces the initial formaldehyde content of the board from the source.

Using formaldehyde free or low formaldehyde adhesives: The urea formaldehyde resin adhesive used in traditional particleboard is one of the main sources of formaldehyde. The formaldehyde free ENF grade environmentally friendly particleboard adopts new formaldehyde free adhesives, such as MDI adhesive (isocyanate adhesive) or other biological adhesives. These adhesives do not release formaldehyde during production and use, fundamentally eliminating formaldehyde pollution caused by adhesives.

2. Good production process

Optimization of hot pressing process: During the hot pressing process, by correctly controlling parameters such as temperature, pressure, and time, the adhesive inside the board is fully cured, while avoiding the occurrence of formaldehyde caused by adhesive decomposition due to overheating or uneven pressure. The optimized hot pressing process can also make the board structure denser, reduce internal pores, and thus lower the release channels of formaldehyde.

Proper drying treatment: Drying wood raw materials is an important step in the production of particleboard. During the drying process of formaldehyde free ENF grade environmentally friendly particleboard, excellent drying equipment and processes are used to control the moisture content of the wood within a suitable range (generally 8% -12%). Appropriate moisture content not only helps improve the physical properties of the board, but also reduces the increase in formaldehyde emissions caused by excessive or insufficient moisture.

Surface treatment technology: Some formaldehyde free ENF grade environmentally friendly particleboard will use special surface treatment techniques, such as edge sealing treatment, veneer treatment, etc. Excellent edge sealing materials and techniques can seal the edges of the board, preventing the release of formaldehyde from the inside. Veneer treatment can form a protective film on the surface of the board, reducing the volatilization of formaldehyde from the board surface.

3. Strict quality inspection

Internal inspection of enterprises: Enterprises producing formaldehyde free ENF grade environmentally friendly particleboard usually establish a strict internal quality inspection system and conduct formaldehyde emission testing on each batch of boards. Enterprises will be equipped with excellent testing equipment and professional testing personnel to test the boards according to standards or stricter enterprise standards. Only products that pass the testing can enter the market.

Third party testing and certification: In addition to internal testing within the enterprise, formaldehyde free ENF grade environmentally friendly particleboard also needs to be tested and certified by third-party authoritative organizations, such as relevant quality inspection departments or professional certification agencies. These institutions will test the boards according to strict standards and procedures to ensure that they meet the formaldehyde emission requirements of ENF level, and issue corresponding certification certificates. This third-party testing and certification has high authority and credibility, and can provide consumers with reliable quality assurance.

Previous:

Why is odorless E0 grade environmentally friendly…

Next:

Why is it said that moisture-proof green and envi…

Related articles

Related products

+

wechat number:底部微信

Home

Home

Wechat

Wechat

Tell

Tell